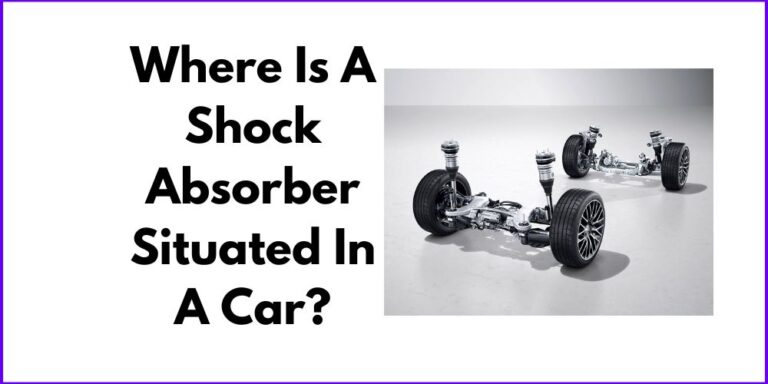

When it comes to owning a travel trailer, there are many components that influence the overall ride quality. Shock absorbers are one of these components and can play a vital role in the overall comfort of your ride. Shock absorbers are designed to reduce the impact from bumps and rough terrain and can help reduce sway when towing your travel trailer.

While it is important to have the proper weight distribution when towing, the added benefit of shock absorbers can make the overall ride more comfortable and potentially safer. In this blog post, we will explore how shock absorbers help sway a travel trailer and the various features that are important when selecting the right shock absorber for your trailer.

We will also discuss some of the common problems associated with shock absorbers and how to identify when they need to be replaced. By the end of this post, you should have a better understanding of the role shock absorbers play in reducing sway on a travel trailer and how to ensure that you select the right shock absorbers for your specific needs.

How do Shock Absorbers help Prevent Sway?

Shock absorbers work by absorbing and dissipating the energy created by road bumps and wind. They do this by converting the kinetic energy of the suspension movement into heat energy, which is then dissipated through the fluid inside the shock absorber. This helps to smooth out the ride and reduce the impact of bumps and other road imperfections on the trailer.

Shock absorbers also play a crucial role in maintaining stability and control of the trailer while towing. When the trailer encounters a bump or other road imperfection, the shock absorbers help to control the movement of the suspension and prevent it from bouncing excessively. This helps to keep the trailer stable and prevent swaying. Additionally, shock absorbers help to keep the tires in contact with the road surface, which improves traction and reduces the risk of skidding or losing control of the trailer.

Overall, shock absorbers help to improve the overall ride quality of the travel trailer by absorbing and dissipating the energy from road bumps and wind, and by maintaining stability and control of the trailer. This helps to reduce sway and make the towing experience safer and more comfortable for both the driver and the passengers.

Do Shock Absorbers Help Sway On A Travel Trailer?

Yes, shock absorbers help sway a travel trailer. They are designed to absorb and dissipate the energy created by road bumps and wind, which helps to smooth out the ride and reduce the impact of bumps on the trailer. Additionally, shock absorbers help to maintain stability and control of the trailer while towing, by controlling the movement of the suspension and preventing excessive bouncing, which helps to keep the trailer stable and prevent swaying. They are also angled to provide sway control, which improves the overall towing experience and makes it safer for both driver and the passengers.

Can You Add Shocks to a Travel Trailer?

Yes, you can add shocks to a travel trailer. Some travel trailers even come with the mounts pre-installed, making the process of adding shocks relatively simple. By purchasing the necessary hardware, including the mounting brackets, nuts and bolts, and the shocks themselves, you can install shocks on your travel trailer to improve its ride quality and stability while towing. It is important to choose the right shocks for your specific needs and to properly maintain them to ensure that they are working at optimal performance.

Types of Shock Absorbers

There are several types of shock absorbers that can be used on a travel trailer, including:

- Twin-tube shock absorbers: These are the most common type of shock absorbers and consist of an outer tube and an inner tube. The inner tube contains the piston and the fluid, while the outer tube surrounds the inner tube and contains the gas. These shock absorbers are known for their durability and relatively low cost.

- Monotube shock absorbers: These shock absorbers have a single tube that houses both the piston and the fluid. They are more efficient at dissipating heat and provide better performance than twin-tube shock absorbers. They are also more expensive.

- Air shock absorbers: These shock absorbers use compressed air instead of fluid to absorb and dissipate energy. They are commonly found on heavy-duty vehicles and are known for their ability to handle heavy loads.

- Electronic stability control systems (ESC): These systems are not shock absorbers themselves but they are systems that work with the vehicle’s suspension to reduce sway and improve stability. They use sensors to detect when the vehicle is starting to lose control, and then automatically apply the brakes to one or more wheels to help bring the vehicle back on course.

Choosing the Right Shock Absorbers for Your Travel Trailer

When choosing the right shock absorbers for your travel trailer, there are several factors to consider:

- Weight: The weight of your travel trailer is an important factor to consider when selecting shock absorbers. Heavy-duty shock absorbers are needed for trailers that are carrying heavy loads or are frequently towed on rough terrain.

- Size: The size of the shock absorbers is also an important factor to consider. The size of the shock absorbers should be matched to the size of the travel trailer and the weight it is carrying.

- Towing conditions: The conditions under which the travel trailer will be towed are also important factors to consider. For example, if the trailer will be frequently towed on rough terrain or in extreme temperatures, heavy-duty shock absorbers will be needed.

It is also important to compare the different types of shock absorbers and their benefits. Twin-tube shock absorbers are known for their durability and relatively low cost, while monotube shock absorbers are more efficient at dissipating heat and provide better performance. Air shock absorbers are commonly used on heavy-duty vehicles and are known for their ability to handle heavy loads. Electronic stability control systems (ESC) can also be considered as an option.

It is important to consult with a professional or consult the manufacturer’s recommendations before making a decision as the best shock absorber for your travel trailer will depend on the specific needs and conditions of your towing setup.

Installation and Maintenance of Shock Absorbers

Step-by-Step Guide: Installing Shock Absorbers on a Travel Trailer

Step 1: Purchase a shock and mount kit from a reputable trailer supply company. The kit should include the shocks, U-bolts, mounts, and required connection hardware. Make sure you have the right size of shocks for your travel trailer’s axles. The Roadmaster kit is available for travel trailers with three sizes of axles: 2 3/8″, 3″, and 3.5″.

Step 2: Use a drill and a ratchet set to attach the lower mounting bracket to the U-bolts and leaf springs. Identify the spring leaves of the trailer, which sit on top of the rear axle, and place the U-bolts so that the curve of the bolt rests on top of the rear axle. One bolt should go on the inside of the leaf springs and the other should go on the outside, facing the wheel. Push the mounting bracket against the leaf springs and feed the U-bolts through the holes. Make sure that the bracket is flush with the leaf springs. Put the respective washers on the U-bolt and secure the bracket with the nuts included. Make sure to torque the bolts to the manufacturer’s specified specifications.

Step 3: Secure the upper mounting bracket by drilling holes in the frame of the trailer. Place the bracket on the frame, mark the holes, and drill them using a low-speed setting. If you have trouble finding the right spot to drill, try measuring the distance between the lower bracket and the top of the frame, and then angling the bracket at a 30-degree angle. This will ensure that the upper end of the shock will fit properly. When drilling, make sure to use a lubricant such as Trick Shot Penetrating, or WD-40 to prevent the metal from getting hot and smoking. Also, use the twist bit or the one recommended by the manufacturer.

Step 4: Insert the shock absorber into the upper and lower mounting brackets. Make sure the shocks are properly aligned and securely fastened.

Step 5: Repeat steps 1-4 for the remaining shocks on the trailer. Make sure to check the alignment and torque on all the bolts and nuts after a few hundred miles of towing to ensure that they are still tightened to the manufacturer’s specifications.

Step 6: Once the installation is complete, test the shocks by towing the trailer on different types of terrain. Make sure to pay attention to how the shocks handle bumps and rough roads and adjust them if necessary. Regularly check and maintain the shocks to ensure they are functioning properly and providing the best ride for you and your passengers.

Maintenance tips

Here are some tips for maintaining shock absorbers to ensure optimal performance:

- Check for leaks: Leaks in the shock absorbers can cause them to lose their effectiveness. Check for leaks regularly by looking for any signs of fluid or air escaping from the shock.

- Check for worn bushings: Worn bushings can cause the shock absorbers to lose their effectiveness. Check the bushings for signs of wear, such as cracks or excessive movement.

- Check for proper alignment: Proper alignment is essential for optimal performance. Check the alignment of the shock absorbers regularly to ensure they are properly aligned with the suspension system.

- Check the oil level: Shock absorbers contain oil that helps to lubricate the internal components. If the oil level is low, it can cause the shock absorbers to wear out more quickly.

- Check for proper air pressure: Air shock absorbers require proper air pressure to function effectively. Make sure to check the air pressure regularly and adjust it as needed.

- Check for proper weight distribution: The weight distribution of the trailer is important for the proper functioning of the shock absorbers. Make sure to check the weight distribution regularly and adjust it as needed.